Beyond Price: Your Strategic Guide to a Yiwu Stock Merchandise Purchasing Agent

Let's be honest. When you hear "Yiwu stock merchandise," you think of one thing: volume and velocity. Getting goods fast and cheap.

But if you're a Procurement Manager, CPO, or someone responsible for your company's supply chain integrity, you know the real game has changed. It's no longer just about cost. It's about managing risk, ensuring compliance, and building a resilient, responsible supply chain.

Hiring a Yiwu purchasing agent is the smart move. But the wrong agent can leave you with container-loads of headaches—from quality rejections and shipping delays to ESG compliance failures that damage your brand.

Here’s the thing: a modern sourcing partner shouldn't just be your "eyes and hands" in Yiwu. They should be an extension of your strategic procurement team.

This guide isn't just about finding an agent. It's about building a partnership that delivers commercial success and strategic security.

The old-school agent waits for your order, finds the cheapest supplier, and ships it out. Their job ends when the container leaves the port.

A strategic partner’s job is just beginning. Think of them as your:

Supply Chain Risk Manager: They proactively audit and monitor suppliers for financial and operational stability.

ESG & Compliance Officer: They enforce your ethical and environmental standards on the ground.

Data & Performance Analyst: They provide you with clear KPIs and insights, not just invoices.

In short, you're not just hiring a service; you're outsourcing a critical business function. This mindset shift is everything.

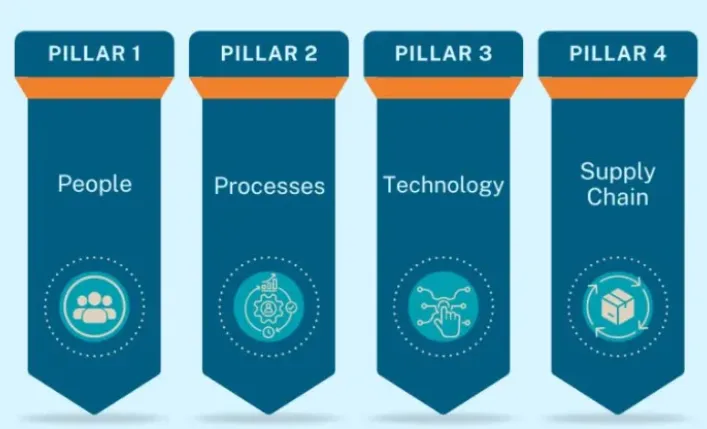

This is the core of how a true partner operates. When you evaluate an agent, ask them specifically how they handle these four areas.

Anyone can find a supplier on 1688.com. A partner conducts proper due diligence.

Our Process:

Beyond the Business License: We do a deep-dive into the factory's operations. We look at their financial health, production capacity, and, crucially, their compliance posture.

The Ethical Sourcing Questionnaire: We don't just show up. We send a pre-audit checklist covering labor practices (overtime, wages, working conditions), environmental management (waste disposal, chemical handling), and facility safety. This separates the serious players from the rest.

The On-Site Audit: We physically walk the production floor, check records, and interview workers. We're looking for the red flags others miss.

What You Can Do: Ask any potential agent for a sample of their supplier audit report. If they don't have a standardized one, that's your first warning sign.

"Quality is good" is a meaningless promise. You need data.

Our Process:

Defined Inspection Protocols: We use AQL standards for pre-shipment inspections, but the real magic happens during production. We implement DUPRO (During Production) checks to catch issues before the entire run is complete.

Transparent KPI Reporting: We don't just say "it went well." We give you a dashboard with:

On-Time Delivery (OTD) Rate

First-Pass Yield (FPY) – the percentage of units that pass inspection the first time.

Corrective Action Request (CAR) Closure Time – how long it takes to fix a found issue.

Digital Evidence: Every inspection includes time-stamped, geo-tagged photos and videos. You see what we see, in real-time.

Radio silence between order and shipment is unacceptable.

Our Process:

Structured Communication Schedule: You get a weekly status report by default, and a monthly performance review call. For critical issues, we have an immediate escalation protocol.

A Single Point of Contact: You have a dedicated Project Manager, but you also have visibility into our entire team. No more getting stuck because one person is on holiday.

No Surprises Policy: We flag potential delays the moment we see them – be it from material shortages, labor issues, or port congestion.

The cheapest freight option is often the most expensive in the long run.

Our Process:

Total Landed Cost Analysis: We don't just quote you FOB price. We help you model the entire landed cost, including duties, tariffs, and domestic freight, so you understand the true cost of your goods.

Logistics Partner Vetting: We work with freight forwarders who have a proven track record in your specific product category and destination port.

Consolidation Expertise: We expertly consolidate goods from multiple suppliers into single shipments, saving you significant money on logistics.

Use this checklist. It will save you months of trouble.

Step 1: Align Internally. Before you talk to anyone, get clear on your non-negotiables. What are your must-have ESG standards? What is your target defect rate? What OTD is critical for your business?

Step 2: The Strategic RFP. Don't just ask for a price list. In your Request for Proposal, include questions like:

"Walk me through your factory audit process for a new supplier."

"What specific KPIs do you report on, and how often?"

"Show me a sample (anonymized) quality control report."

Step 3: Capability Validation. Have a video call with the team that will actually handle your account. Ask them to run through a hypothetical problem: "What would you do if you found a critical quality failure one week before shipment?"

Step 4: The Pilot Order. This is non-negotiable. Start with a small, non-critical order. Test their entire process—communication, reporting, problem-solving, and final output. The goal is to see their machinery in action.

Step 5: Build the Partnership. Once you've validated their capabilities, transition from a transactional relationship to a strategic one. Share your long-term goals. The more they know, the more value they can add.

Sourcing from Yiwu is a powerful way to drive your business forward. But in today's world, the lowest price without strategic control is the highest risk.

You need a partner who cares about your supply chain as much as you do. You need a partner who provides not just products, but security, transparency, and a competitive edge built on responsibility.

Ready to move beyond just comparing prices?

Download our free, editable checklist: "The Strategic Sourcing Agent Vetting Checklist & ESG Supplier Questionnaire." Use it to interview us or any other agent. Arm yourself with the right questions.

Schedule a 30-minute, no-obligation consultation. Let's discuss your specific sourcing challenges. We'll show you how our four-pillar approach can de-risk your Yiwu supply chain and deliver not just goods, but peace of mind.

1. Q: What's the most secure payment structure when working with a new Yiwu agent?

A: We recommend a staggered payment: 30% deposit to secure the order, 70% balance against a copy of the Bill of Lading. This protects you from paying the full amount before production is complete and the goods are shipped. Never pay 100% upfront.

2. Q: How do you handle intellectual property (IP) protection for our designs?

A: Before sharing any designs, we have suppliers sign a strict NDA and IP protection agreement. We also compartmentalize production—different factories make different components so no single supplier has the full blueprint. For critical items, we can register your design with Chinese customs to prevent counterfeiting.

3. Q: What happens if we receive a container of defective goods? What's the recourse?

A: This is why pre-shipment inspections are non-negotiable. However, if defective goods slip through, the recourse depends on the contract. With our service, our liability is tied to our inspection failure. We would immediately pursue the supplier for a refund or re-production. Having a clear, signed quality agreement upfront is your best defense.

4. Q: Can you manage the entire import process, including customs clearance in our country?

A: We handle everything up to the port of destination (DAP terms). For full door-to-door service (DDP terms), we partner with trusted freight forwarders in your country who handle final customs clearance and delivery. We manage that relationship for you, ensuring a seamless handoff.

5. Q: We need specific certifications (like CE, UKCA, FDA). Can you guarantee our products will pass?

A: We can't guarantee pass/fail, as that depends on the product's fundamental design and materials. What we do guarantee is the process: we will only source from factories proven to produce for your target market, review all test reports from accredited labs with you before shipment, and manage the documentation flow to ensure compliance.

6. Q: How do you handle sudden price increases from suppliers mid-production?

A: A professional supplier will honor the price quoted in the proforma invoice (PI). Sudden increases are a major red flag. Our job is to negotiate and shield you from this. We lock in prices with the PO and maintain strong relationships so suppliers honor their quotes. If a raw material cost genuinely spikes, we present the evidence and negotiate a fair cost-sharing solution, always with your approval.

7. Q: Is it possible to source lower than the stated MOQ (Minimum Order Quantity)?

A: Often, yes. It usually comes at a 10-20% price premium. The best approach is to present a clear roadmap for future volume. We can negotiate a lower initial MOQ by showing the supplier the potential for a long-term, high-value relationship. It's a conversation, not a hard rule.

8. Q: Do you work with buying agencies from other countries, or only directly with end-clients?

A: We work with both. For international buying agencies, we act as your on-the-ground execution partner. We provide the granular data, factory access, and logistical muscle, while you manage the client relationship. We sign NDAs to protect your clients.

9. Q: How do you mitigate the risk of a single supplier failing?

A: We advocate for dual-sourcing for critical components. This means developing two qualified suppliers for the same item. It costs a little more in management effort, but it completely de-risks your supply chain from factory fires, sudden closures, or capacity issues.

10. Q: What's your policy on agents taking commissions from factories?

A: Our fee is 100% transparent and paid by you, the client. We do not accept commissions or kickbacks from factories. This is fundamental to our model—it ensures our advice is unbiased and that we are always negotiating on your behalf to get the true best price.

11. Q: Can you help us with product development and sourcing non-stock, custom-made items?

A: Absolutely. Yiwu is fantastic for stock, but the surrounding regions specialize in custom manufacturing. We can help you with prototyping, material sourcing, and production for custom goods, connecting you with the right specialized factories beyond the market.

12. Q: How far in advance should we contact you before we need the goods in our warehouse?

A: The sooner, the better. A good rule of thumb is to contact us at least 12-14 weeks before your ideal stock arrival date. This allows 2-3 weeks for supplier sourcing & sampling, 4-6 weeks for production, 1 week for QC, and 4-5 weeks for shipping. Rushing this process is the most common cause of quality failures.

Contact us

Call Us: +86 193 7668 8822

Email:[email protected]

Add: Building B, No.2, He Er Er Road, Dawangshan Community, Shajing Street, Bao'an District, Shenzhen, China